|

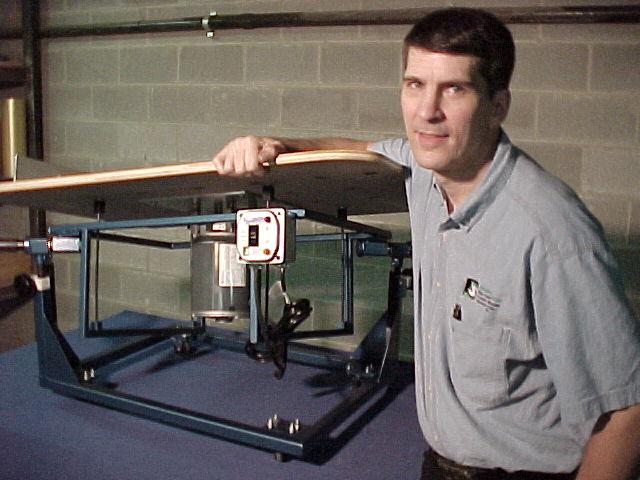

This custom-built jogger,

engineered by Johnston Services' owner, Ben Johnston, is a redesigned version

of existing, but shortsighted designs. He felt the industry needed a superior, more versatile jogger that would handle more than

just the large sheets. More photos are at bottom of page.

Now, there is a better

way to collect your laminator's output, the Vari-Jogger. This vibrating

catch table will pay for itself in a few months by reducing the amount

of mindless effort required by an employee, who has more productive things

to do. The Vari-Jogger gets its name from the many variations it

can be configured to handle and will work with any known sheet separator

or cutter. With the Vari-Jogger behind your cutter, your product

output stacks up neatly. It works best with a cutter equipped with

an exit conveyor because these bring the cut sheets out in the same position

every time, but can be helpful for cutters without exit conveyors as well.

(After market exit conveyors available upon request for many cutters.)

Working example: If you

have 8-1/2" x 11" sheets that have to be 3 hole drilled after laminating,

an exit conveyor and the Vari-Jogger will dramatically reduce the time

required for your operators maintaining registration alignment of the output

stack.

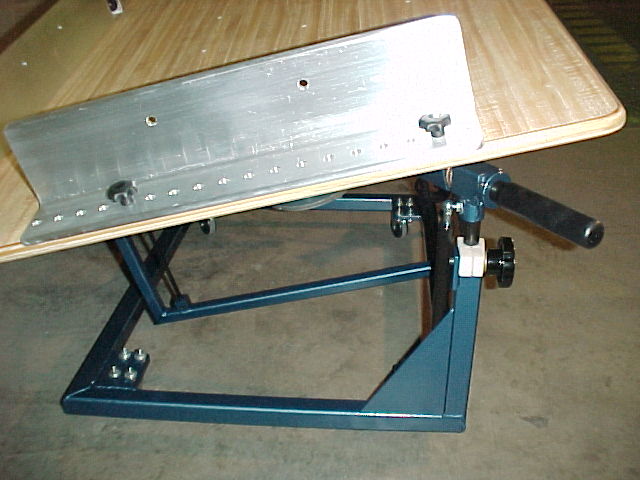

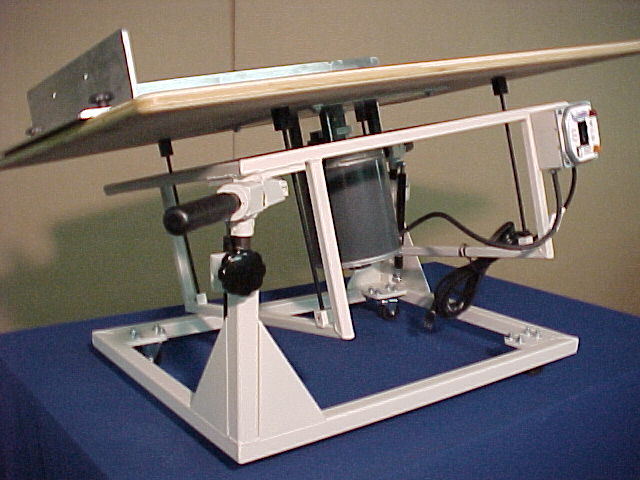

It is able to receive sheets

ranging in size from 2" x 3" up to 28" x 40" by simply adjusting the L-angle

end stops so that the sheets are caught at the top of the jogger, rather

than having to make it all the way to the bottom - especially important

for smaller sheets like 8-1/2" x 11."

The tilt angle can be changed

easily, and will hold that angle.

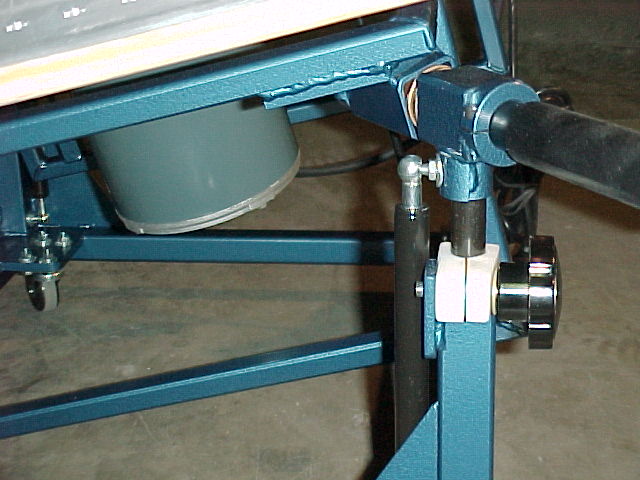

The height can be adjusted

to accommodate different sheet separators or situations. The weight of the table is

pushed up by gas springs so it is easy for one operator to make the adjustment.

To raise, simply loosen both clamp knobs and the springs push it up. To

lower, loosen the clamp knobs, press down on the table top and retighten clamp

knobs at the desired height. The top corner of the Vari-Jogger (some what dependent on the angle of

tilt) ranges from about 24" from the floor to as high as 30." It can be

built higher if needed.

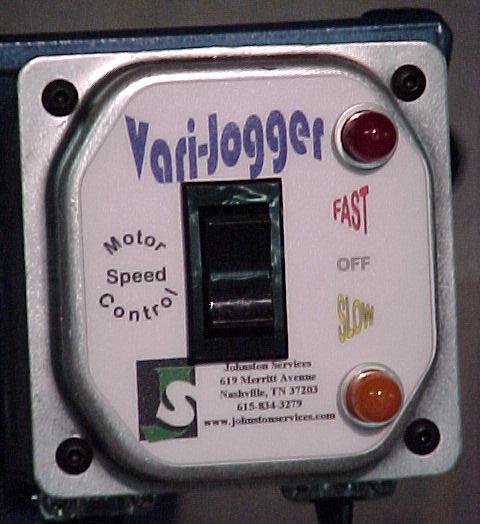

The motor has two speeds.

The slower speed is useful when running polypropylene laminations that

are more prone to the buffing scratches imparted to the bottom sheets.

The Vari-Jogger has indicator

lights to make its operation apparent from a distance (red for fast, amber

for slow). Another reason for the indicator lights is that it is so quiet when

empty (especially with typical background noise), that it could easily be left

on and forgotten, running needlessly, when not in use.

There are two fixed caster

wheels and two swivel casters for easy steering to another location, yet

it's stable enough to stay where you put it (without vibrating out of position).

The benefits of this great

machine do not stop here: It also provides a great foot massage during

breaks!

The Vari-Jogger is covered

for One (1) year against manufacturing defects.

NEW!! The frames are now Powder

Coated! The standard color configuration

is Black Satin finish on the frame, with Matte White Formica top.

Production

Notice: Due to recent move, my production facility is very cramped. It will just

take a little longer to produce the Vari-Jogger. There are 90 machines placed with

more than 40 different customers. If you would like to obtain references,

several have agreed to talk to potential buyers. They can assure you the

wait will be worth it. Call for details.

Effective July 01, 2011 the price of the Vari-Jogger will have to be

determined per sale, with a quantity

discount still available for multiple machines ordered. Material costs are out

of control. Please contact me for current pricing.

Payment terms are Pre-pay with delivery in 6 - 8 weeks. Again,

other customers can testify that this works. Other arrangements can be made,

but the total cost to the customer is higher if not fully prepaid.

Shipping must be arranged and paid by customer via freight truck

line of your choice. The Vari-Jogger is carefully contained in an enclosed in

a triple thickness corrugated box with wood framework crate, class 85, shipping weight is

under 250 lbs.

Crate dimensions are: 36" W x 48" L x 32" H.

ORDERING

INSTRUCTIONS:

Please call, ask questions.

1. Email your Purchase Order with your company information.

Please include your name, company address, phone and email

address.

2. An invoice with your PO # on it will be returned to you via email.

3. Send check payable to Johnston Services to the address shown on

the main web page and the invoice.

4. Shipping date is based on 6 - 8 weeks from date your check is received.

Curious

about our competition? We're proud of what we build, and feel

it is the best machine, by far, for the price. This is our only direct competitor.

They would rather sell a whole system than just a jogger. These are made for

large sheets ONLY. They do not work well with various applications.

http://www.dkgroup.com/igsbase/igstemplate.cfm/SRC=DB/SRCN=/GnavID=7/SnavID=3

You can see their jogger at the end of their System 3210. Unfortunately, you can't get much detailed information about their

jogger. Even the brochure they used to send out reveals little about its

features, because, frankly, it has few to offer compared to the Vari-Jogger.

Below, you can find

many photos of all the Vari-Joggers as they have evolved and improved. By clicking on any of

these thumbnails, you can view an enlarged view and learn a little more

about the Vari-Jogger.

The red joggers are the year model 1999, and are the only photos

I have of the jogger in action behind the Autofeeds cutter.

The green joggers

represent the year model 2000 machines with the gas lift springs and

"Hammered Steel" finish paint. We have since gone to powder

coating starting in 2005.

The blue joggers are photos of the 2001 models with

the improved lift extension clamps that allow for smooth lift operation. This is the model Vari-Jogger that

made its international debut in September 2001 in the Autofeeds booth during the Print 01 show.

The "white" joggers are photos of the model being used

in the Autofeeds trade show booth and if you ask Autofeeds for a jogger with

their laminating system, this is what you get. This is the same model

currently in production, with some very minor changes. The best

modification is that they are all powder coated for a very good looking and

tough finish.

|